Services

Heavy Duty. Custom Designed

Avon Engineering mechanical systems experts provide the industrial material handling equipment support services needed to keep steel mills, aluminum mills, mineral processing, paper mills, and other heavy industrial operations productive. We manufacture a host of complementary parts including gearing, gearboxes, sheave nest assemblies, as well as crane and track wheel assemblies.

The advantages we offer include:

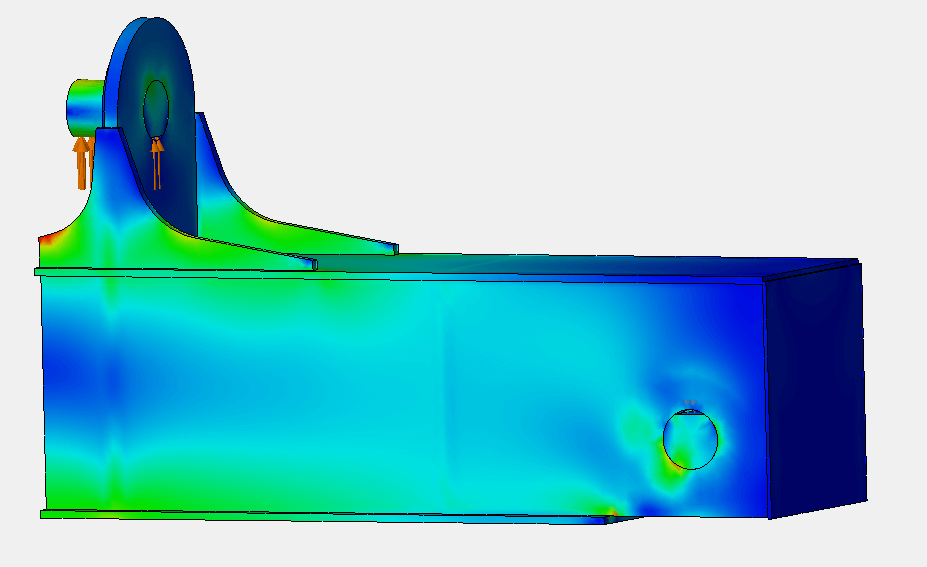

- Access to the latest technology, including Finite Element Analysis (FEA), Portable 3-D Scanner, Coordinate Measuring machines (CMM)

- Each part is photographed, mechanically and nondestructively tested by onsite certified inspectors as required, and reverse engineered as necessary

- Customers are provided with a comprehensive, itemized inspection report with failure analysis and photos

- Certification of below-the-hook lifting devices can be provided

We are available to serve our customers’ standard, rush, emergency, and breakdown needs.

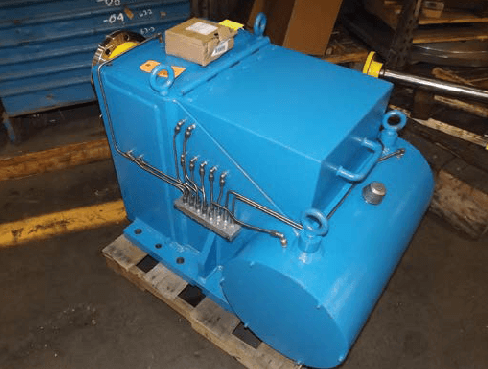

Gearbox Repair

Gearbox repair services encompass the inspection, diagnosis, maintenance, and restoration of various types of gearboxes, ensuring optimal performance and longevity. Skilled technicians utilize advanced tools and techniques to repair issues like wear, misalignment, and noise. Services can range from minor adjustments to complete overhauls, catering to automotive, industrial, and marine applications. Timely repairs enhance efficiency, reduce downtime, and prevent costly replacements, supporting the smooth operation of machinery and vehicles.

Request Quote

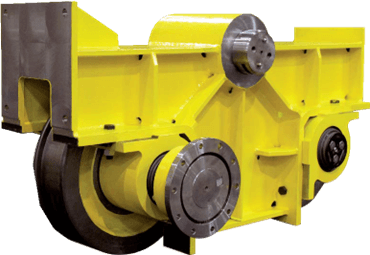

Crane Wheel Assemblies

Crane wheel assemblies are crucial components in overhead cranes, enabling the efficient and safe movement of heavy loads in industrial environments. They consist of wheels, bearings, axles, and other essential parts that ensure smooth operation. Designed to withstand intense stress and wear, these assemblies are meticulously engineered for durability and reliability. Proper maintenance is paramount, as it ensures optimal performance, enhances safety, and extends the operational life of crane systems.

Request Quote

Engineering Services

Engineering services encompass a range of specialized solutions, including design, analysis, and consultation, tailored to optimize the functionality, safety, and efficiency of structures and systems. Engineers, equipped with advanced tools and expertise, address complex challenges in various sectors, such as construction, manufacturing, and technology. They ensure projects are executed to specifications, compliant with regulations, and sustainable. These services are pivotal for innovation, operational excellence, and the successful completion of engineering projects.

Request Quote

Electrical Automation

Heavy-duty mill equipment often benefits from electrical automation services, offering substantial advantages in industrial settings. Automation enhances efficiency and precision by reducing manual labor requirements, resulting in increased productivity. It also ensures consistent and accurate operations, reducing errors and downtime. Electrical automation services enable real-time monitoring and control, improving safety and minimizing the risk of accidents. These services can be tailored to specific mill processes, optimizing workflow and overall equipment performance.

Request QuoteOn-site NDT Inspections

On-site Non-Destructive Testing (NDT) inspections offer significant advantages in heavy-duty mill equipment maintenance. They provide a thorough assessment of equipment integrity without the need for dismantling, minimizing downtime. NDT inspections can detect hidden defects, cracks, and wear, preventing catastrophic failures and accidents. They also help extend the lifespan of critical equipment, ensuring long-term reliability and reducing replacement costs. On-site NDT inspections are indispensable for optimizing safety, productivity, and cost-effectiveness in heavy-duty mill operations.

Request Quote

On-Site Machining

On-site machining for heavy-duty mill equipment presents numerous advantages. It minimizes downtime by eliminating the need for equipment disassembly and transport to off-site facilities. Precision on-site machining ensures optimal equipment alignment, reducing wear and improving performance. This approach also facilitates quick repairs, preventing prolonged production interruptions. On-site machining services can be tailored to specific mill needs, offering cost-effective solutions and extending the lifespan of critical equipment.

Request Quote