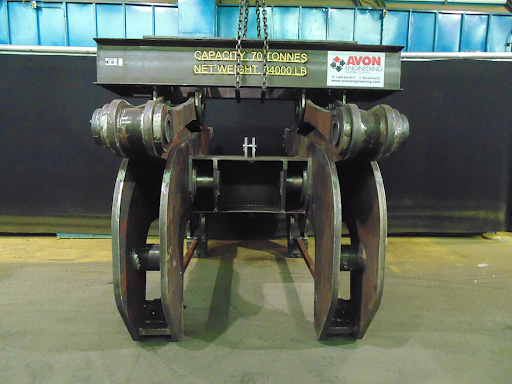

Slab Tongs

Heavy Duty. Custom Designed

Handling steel slabs and other large flat stock safely and efficiently is a critical task in metal production and processing environments. Avon Engineering designs and manufactures slab tongs tailored to the demands of steel mills, rolling operations, forging plants, and heavy-duty manufacturing facilities. Each unit is built to deliver reliable performance under extreme conditions and heavy loads.

Handling steel slabs and other large flat stock safely and efficiently is a critical task in metal production and processing environments. Avon Engineering designs and manufactures slab tongs tailored to the demands of steel mills, rolling operations, forging plants, and heavy-duty manufacturing facilities. Each unit is built to deliver reliable performance under extreme conditions and heavy loads.

Slab tongs from Avon Engineering are purpose-built lifting solutions designed to grip, lift, and move heavy slabs with precision and control. They are available in a variety of design styles, including automatic, hoist operated, cable operated, motorized, and hydraulic operated. Gripping varies from 2-point or 4-point grip configuration. Slab tongs may hang from a single crane hook, double crane hooks or reeved directly into the crane.

- Automatic Slab Tong – Designed to operate with an automatic latch, which keeps the tong open when descending onto the slab. The latch is released when the tong comes to rest on top of the steel slab and begins to squeeze the legs.

- Hoist Operated Slab Tong – Operates with the electric hoist mounted directly on top of the tong. A wire rope from the hoist keeps the tong open as it descends onto the slab. As the tong closes the wire rope will go slack and remain slacked until the slab is laid to rest.

- Dragline Operated Slab Tong – Works similarly to a hoist operated slab tong but with the hoist mounted on the crane trolley rather than the tong. A wire rope runs directly from the crane down through the center of the tong to keep it open as it descends onto the slab. As the tong closes the wire rope will go slack and remain slacked until the slab is laid to rest.

- Motorized Slab Tong – Functions by using worm gear motors with a jack screw system to actuate the tong.

- Hydraulic Operated Slab Tong – Engineered to operate using an electric driven hydraulic system mounted on the tong.

Benefits of Slab Tongs from Avon Engineering

Our slab tongs enhance safety and operational efficiency by:

- Providing positive grip on hot or cold slabs without damage

- Reducing manual labor and material handling time

- Enabling single-operator control of heavy slab movement

- Increasing throughput in slab handling and staging operations

Avon’s slab tongs are engineered for heavy-duty performance and long service life:

- Engineered to meet ASME B30.20 standards for below-the-hook lifting devices

- Lifting capacities from a few tons to 100 tons or more

- Designed for slabs of varying thicknesses, widths, and temperatures

- Mechanical and motorized models available

- Equipped with high-strength gripping surfaces and optional wear-resistant liners

Purchase Considerations

Selecting the right slab tong requires careful evaluation of application needs and operating conditions:

- Slab Dimensions: Know the typical length, width, thickness, and weight of the slabs to be handled.

- Temperature Conditions: Choose tong materials and coatings suitable for hot mill or cold stock applications.

- Grip Mechanism: Decide between automatic/mechanical engagement or powered operation based on your handling processes.

- Lifting Equipment Compatibility: Ensure slab tongs integrate with your overhead crane or hoist system.

- Cycle Frequency: Consider the duty cycle and required durability for frequent lifting applications.

System Requirements

To operate slab tongs effectively and safely, consider the following system requirements:

- Overhead Crane Capacity: Verify the crane has the lifting capacity and hook height to accommodate tong and load.

- Work Area Clearance: Allow space for tong expansion, slab insertion, and safe lifting paths.

- Operator Visibility and Control: Position operators or control systems for clear line-of-sight and responsive handling.

- Maintenance Access: Design space for tong inspection, lubrication, and part replacement.

Integration with Existing Operations

Avon Engineering ensures your slab tongs work smoothly within your current operations:

- Custom Engineering: Each tong is tailored to your slab sizes, crane hook design, and facility layout.

- Automation Ready: Motorized slab tongs can be integrated with automated crane systems or remote control interfaces.

- Operator Training: We offer training and documentation to support safe and proper operation.

Frequently Asked Questions

Partner with Avon Engineering

Avon Engineering’s slab tongs deliver the strength, precision, and safety required for reliable slab handling in the most demanding industrial environments. Whether you need to lift freshly rolled hot steel or cold-formed slabs for shipping and storage, we build the right tool for the job.

Contact us today to learn how a custom-engineered slab tong from Avon Engineering can enhance material handling in your operation.